Load cell technology for sim racing pedals

Braking is where races are won or lost. In the heat of competition, being able to stop precisely, lap after lap, is what separates a smooth, consistent driver from someone constantly fighting their inputs.

What’s the secret behind precision braking in high-end sim racing setups? Why do some pedals just feel more natural, consistent, and intuitive?

The answer lies in a small but powerful piece of hardware: the load cell.

What Is Load Cell Technology?

In simple terms, a load cell is a sensor that measures force. In sim racing pedals, that means it doesn’t measure how far the pedal moves, but how hard you press. The force applied is converted into a digital signal, which is then interpreted by your racing software.

This matters because in real cars, especially in motorsports, drivers don’t brake based on pedal travel. They brake by applying a specific amount of force. That force-based input becomes muscle memory. Over time, your body learns what 50%, 70%, or 100% braking effort feels like – making your braking more accurate, repeatable, and consistent from lap to lap.

Because load cells rely on applied force rather than position, they offer a method that is not only precise but also durable. With no moving parts to wear out, load cells require minimal maintenance and are a top choice for sim racers who prioritize long-term performance and training consistency.

Reasons to Choose Load Cell Technology

Control is a core part of driving performance, and consistency is what separates average laps from winning ones. One of the biggest advantages of load cell technology is that it measures force rather than pedal position. This makes braking easier to control, more repeatable, and more natural to learn. Over time, your muscles remember how much force to apply, allowing you to deliver the same braking input lap after lap.

This makes driving more intuitive and reduces mental effort. You’re not thinking about the pedal — you’re reacting to the car. In sim racing, where you can’t rely on g-forces or seat-of-the-pants feedback, that intuitive braking feel becomes essential.

Built to Last

Durability is another key benefit. When you’re practicing for hours or racing competitively, you need hardware you can trust. Load cell sensors are typically made from high-strength materials like stainless steel. Aluminium is also commonly used because of its lightweight, corrosion resistance, and elasticity, while offering excellent strength and can handle repeated pressure and force without bending or breaking. This construction helps pedals resist wear from friction or mechanical stress, making them far more reliable than potentiometers, which degrade over time due to moving parts.

Hydraulic pedals offer a very realistic feel by using brake fluid or oil in a closed-loop system. Although both hydraulic and load cell pedals provide accurate input, hydraulic pedals require more complex maintenance, including bleeding and leak prevention.

Why Kilograms Don’t Matter for Brake Pedals

When it comes to sim racing pedals, the number of kilograms needed to press the pedal isn’t the key factor. What truly matters is the maximum load capacity of the load cell and how well you can feel and consistently apply the braking force while staying comfortable during long sessions. Real braking is about controlling force, not just pushing the pedal to a certain position or weight.

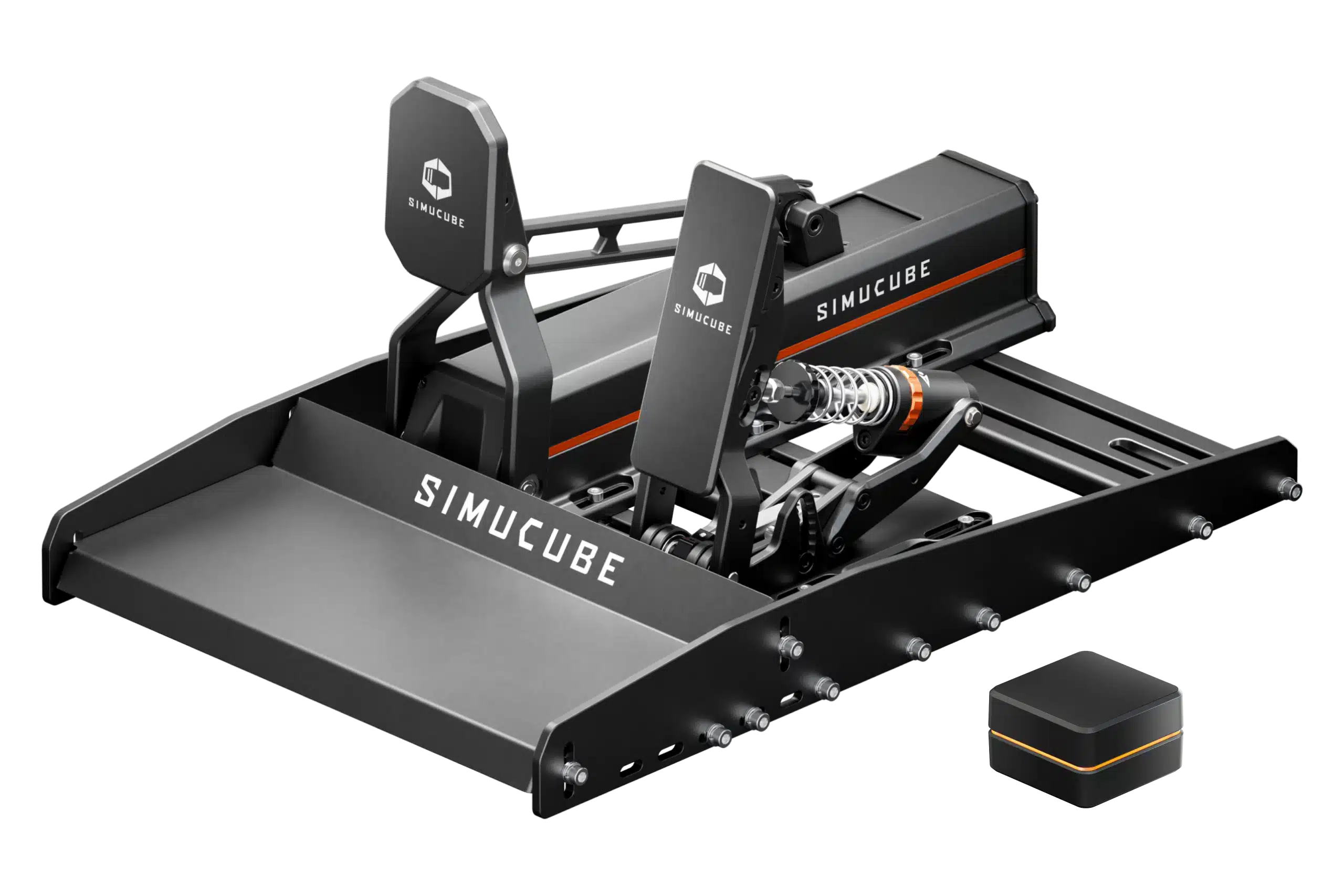

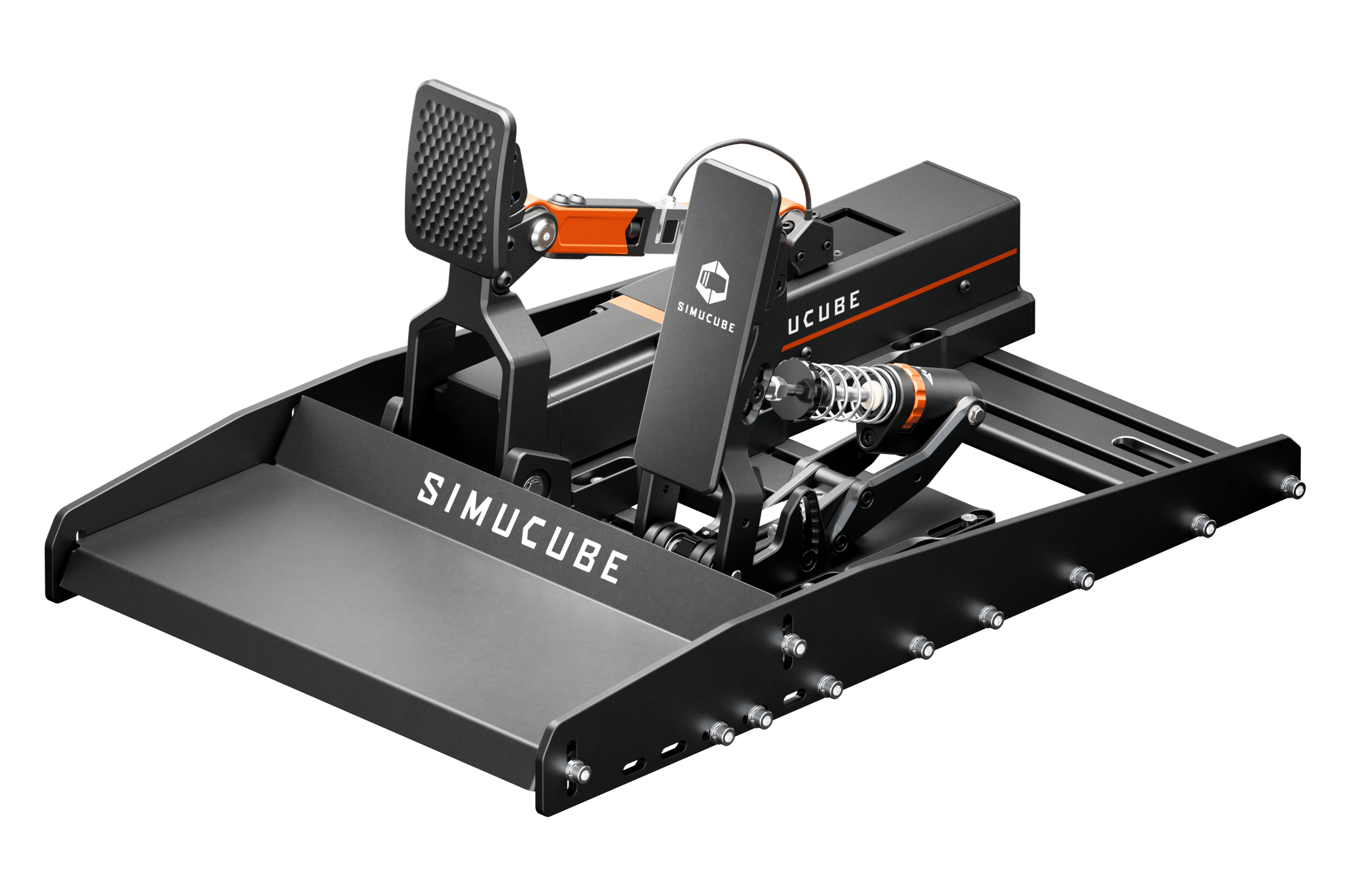

Both pedals, Simucube ActivePedal Pro and Ultimate, use S-type load cells with maximum capacity of 2000 N and are made of stainless steel. This number shows the actual force measured, not just the pedal “weight” like the 110 kg or 200 kg figures often quoted in the market.

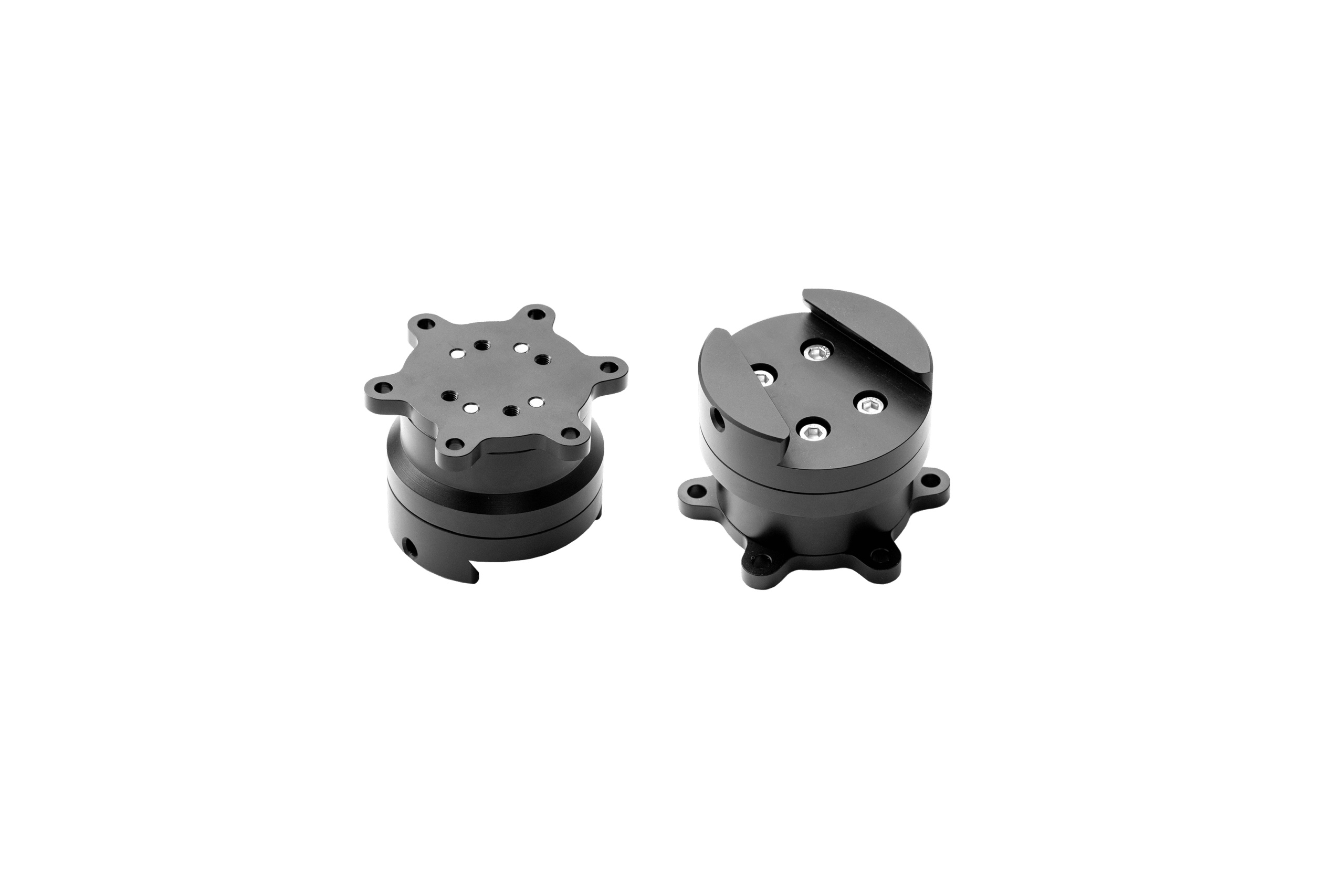

At Simucube, the load cells are not placed directly under the foot. Instead, Simucube optimizes their placement for accuracy, measuring forces digitally across multiple dimensions through software. Most traditional pedals place the load cell directly under the foot, meaning they measure only the direct vertical force applied. That setup works, but it’s not always accurate, as in real use, your foot doesn’t always press straight down.

In addition, in the ActivePedals traditional mechanical systems such as springs and fluids are replaced with a motor-powered setup. A motor-driven feedback system is combined with software-defined pedal feel. This allows adjustment of pedal force and behaviour through software rather than physical components, extending pedal lifespan.

To sum up and answer the question, “How does load cell technology improve braking performance in sim racing?” see the table below.

If you want to learn more about high-end sim racing pedals, check out our blogs:

How does load cell technology improve braking performance in sim racing?

| Aspect | Explanation |

| Core function | Measures force, not pedal travel |

| Realism | Mirrors real motorsport braking – drivers brake based on applied force, not distance |

| Muscle memory | Promotes consistent, repeatable braking by training your body to feel force levels |

| Control & intuition | Braking becomes more natural and reactive — less mental effort, more consistency |

| Durability | No moving parts = minimal wear, low maintenance. Made with high-strength materials like stainless steel and aluminium. |

| Sensor placement | Simucube places load cells to measure multi-dimensional forces for greater accuracy |

| Software-adjustable feedback | Motor-driven feedback and software allow fine-tuning of pedal feel, adapting to different preferences and styles |

| Pedal “Weight” vs. load capacity | Kilograms don’t define quality – the key spec is maximum load capacity (e.g., 2000 N), reflecting real measurable force |

| Best fit for | Competitive / League Racers |